|

Custom furniture is more popular than ever as a cost-effective solution to fit out a commercial space. This is also combined with the fact more and more businesses are opting to buy local. There are clear benefits to this, supporting local means supporting Australian jobs and the economy, and buying Australian made furniture means you can have greater trust in the product. But what goes into making a custom piece and what makes custom pieces so special? We sat down with our newest supplier Klaro Industrial Design (KID for short) to discuss some of these burning questions. After a brief great tasting coffee (locally bought of course) and a tour of the showroom we got down to business.

A second common challenge which is often missed is access to the site – After building the units they then must be delivered and installed in the space. Entering and installing in the space needs to be accounted for, for example you will not be fitting a 6m specified table in a lift anytime soon. Therefore, from the beginning, said table must be designed so it can be broken down initially to be loaded into the lift, then it needs to be assembled on site – This needs to be straightforward as time constraints must be factored in. As all KID products are designed for longevity, we need to consider a client’s current space may be temporary, so at some point down the line, these pieces need to be easily dismantled without breaking – and yes, reassembled elsewhere. A third consideration, which at the end of the day is common across all creative briefs is client translation – You sometimes need to translate a drawing to what I call supply and fit language. There once again needs to be a happy medium between cost, lead time and design intent. Sometimes a realignment is needed before we begin the project. An extension of this is relationship building (this is common again in any discipline I feel. A relationship needs to be established, properly nurtured, and maintained between clients, suppliers, and the general team. As you develop relationships you better understand abilities, limitations and improves your ability to predict and therefore adapt.

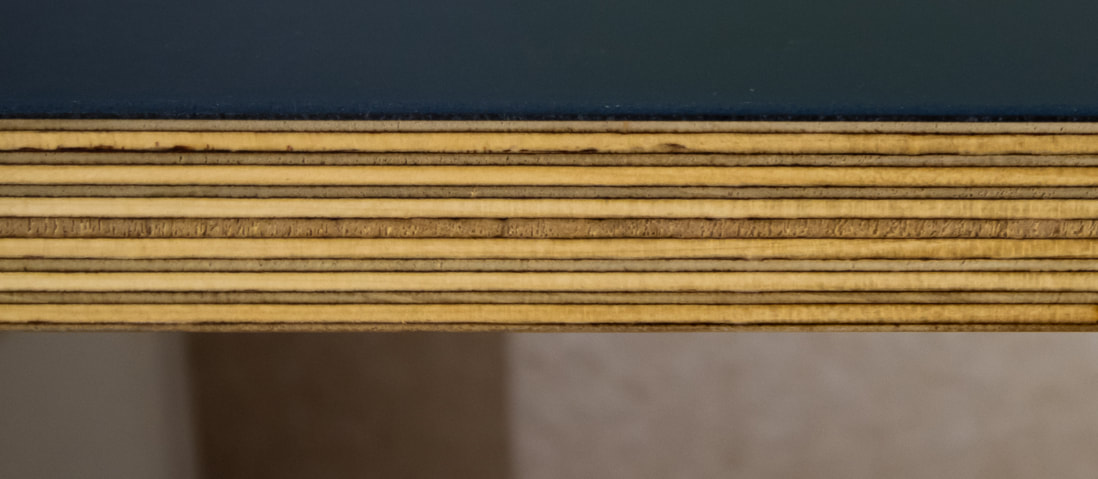

Where do you source your materials from? Ideally all materials are sourced locally, (Timber – Victorian ash) steel, various fabrics (eg wool) because in the end it all feeds back to the local community, which benefits us all. I have a focus on recyclability and ensuring the material is biodegradable, my materials will hopefully see a second life after my product has ended. My focus is ethical and environmental sustainability. Even international timber needs to be ethically sourced. Fabric, foam, MDF, steel and timber are generally local. Fabric can come from international sources but can be recycled if the user decides to do it. For example, the felt I use is 70% recyclable PET.

Finally, what’s the turnaround time for a custom piece? All KID products have 4-5 weeks from confirmation to delivery and install. However, there are many factors that play into this, for example does the client want to source local or overseas components. But generally, we aim for 4-5 weeks. As we closed off our conversation, I noticed how warm, welcoming, and comfortable the pieces were – A clear intention and by product of well-considered design and functionality. Also noting the trend in workspaces adopting an inviting aura to better facilitate a productive environment.

And without a doubt keen to see what’s next on the menu of KID products. Montage offers a wide range of KID furniture, from workstations and tables to seating and storage – plus much more. Check it out here!

0 Comments

|

Access Octomono Masonry Settings

AuthorMontage Commercial Interiors. Archives

August 2021

Categories |

Site Map |

ContactSydney - Head Office 380 Princes Hwy, St Peters, NSW, 2044

Phone +61 2 9557 2622 Email sydney - [email protected] Melbourne 32 Viking Court, Cheltenham, 3192 VIC Phone +61 3 9965 0917 Email - [email protected] |

SIGN UP TO OUR MAILING LIST |

RSS Feed

RSS Feed